- Home

- About Us

About Us

For many years, we have been focusing on the research and development and production of PCBN Cutting tools. REALY's core team and main technical personnel all have bachelor's degree or above, and 60% of them have graduate degree or above. Some technical personnel have received professional technical and management training abroad. By virtue of our professional knowledge and years of work experience, we can design and produce products satisfied by customers in the shortest time according to their different PCBN tool requirements.

More than 60 processing and testing equipment come from Switzerland, Taiwan, Japan and other countries' famous brands. The equipment detection link is complete, and the machining accuracy of the equipment can reach the international level. So that REALY can ensure to provide customers with the best quality tool products.

At present, REALY has the production capacity of cutting toolsets of 1 million pieces annually. Products have been exported to Germany, the United States, Switzerland, India and Japan, the republic of Korea, Vietnam, the United Kingdom, Russia and more than 20 countries and regions.

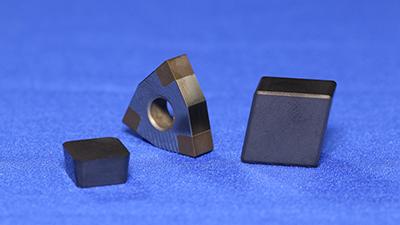

PCBN is a new kind of super hard cutting tool material which is synthesized artificially developed after synthetic diamond. Its hardness is hv3000-5000, second only to diamond. CBN has high fracture resistance, abrasive resistance, heat resistance and good chemical stability. It is widely used for cutting cold cast iron, high temperature alloy and other cutting operation of materials. Compared with carbide cutting tools, the machinability of PCBN is better than ceramic cutting tool. Although Ceramic cutter has good thermochemical stability, its toughness and hardness are not as good as PCBN cutting tool. PCBN Cutting Tool is more suitable for cutting workpiece whose hardness is higher than HRC60, especially in automatic processing and high-precision processing. In addition, under the same condition of rear blade surface wear, the residual stress on the surface of PCBN cutting tool after cutting is more stable than ceramic cutters.